Friday, an architect asked for help researching a question about metal stud installation for interior partitions. The question was the result of a site visit. The resolution needed to be speedy. Monday the contractor planned to install gypsum board, covering the framing.

The architect sent the metal framing submittal for reference to help with the research. The architect got his answer. But the submittal opened many more questions having nothing to do with the architect's question.

Procedures Matter

The transmittal indicated the submittal was Spec./Item 092216 Part II. This suggests that all products specified in the section should be expected to be included in the submittal. The submittal was limited to studs and runners, despite the spec Part II having deflection track and ceiling suspension systems as well.

The submittal from the subcontractor was the manufacturer's brochure including information for every stud and track the manufacturer offers. Not one mark was made and the transmittal did not indicate what products were offered for this particular project.

The contractor marked the PDF submittal with a single PDF comment "Reviewed (2014.0407)" with the contractor's name. The specifications required much more for the contractor's review and more data as part of the contractor's "Approval" stamp to be applied to the submittal. The contractor's approval required a statement that the submittal was checked for compliance with the Contract Documents.

The architect applied a submittal stamp and marked "No Exceptions Noted."

Great! The subcontractor, contractor, and architect all agreed that every stud and runner in the submittal was required for the project. Plus they all agreed that following the specified procedures was unnecessary.

What Did the Owner Want?

Specifications document the Owner's requirements. The specification required 33 mil studs with a G60 galvanized coating, complying with ASTM C645.

What Was Offered?

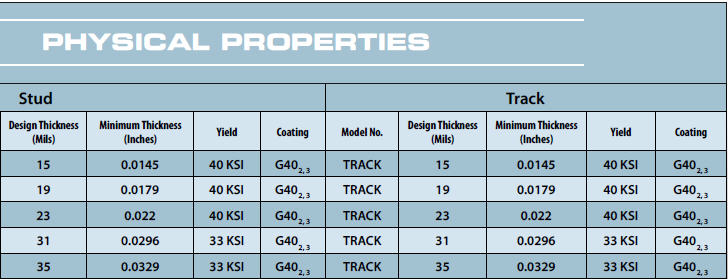

From the (cropped) submittal, the subcontractor offered, the contractor reviewed, and the architect took no exception to the chart below from the manufacturer's brochure.

What framing will be used, and what coating is offered? None of the studs and runners are available in a 33 mil thickness and none are shown G60 galvanized required by the spec. None of the stud designations match those required by the specified reference standard ASTM C645. And the subcontractor and contractor did not indicate what framing would be used.

Notice the footnotes, above. The G40 hot dipped galvanized coating may not be G40, but an equivalent coating instead (footnote 2). However there is no further explanation of what coating is actually being offered for the project. Sure G60 galvanizing is available (footnote 3), but only on special order. Did the contractor place that special order?

So what was installed? Without a site visit it is impossible to know. The manufacturer's literature indicated compliance with ASTM C645, so the required stud markings would tell, but who is checking to know?

Remember the spec included deflection track, yet the submittal included only standard runners. So how did these non-load-bearing partitions accommodate structural deflection? Were they inadvertently made load-bearing?

Owners, Architects: Insist the Specifier be Involved!

So many unanswered questions about this submittal, but note who is asking!

Who better to help review the contractor's submittals than those responsible for writing the specifications used to purchase and install the materials? Specifiers know the technical requirements and the referenced standards. Take advantage of the knowledge.

Ask for help when needed. Even better, require your specifier, as a standard service, to review the contractor's submittals for every project to ensure the owner gets what he paid to receive.