Updated and republished: October 5, 2022

Learning how to write or navigate the mounds of data that is known as construction specifications can be daunting. This data must be easily found and understood by the hundreds of individuals involved in any construction project - not just the contractor, architect, and owner, but the subcontractors, materials distributors, suppliers, manufacturers, and more. Standardized data arrangements allow anyone who is familiar with the standards to find the data quickly - right where it is expected to be found.

The Construction Specifications Institute (CSI) publishes standards to help the industry. CSI tells us how to organize, write, and publish specifications. The American Institute of Architects (AIA) publishes standard agreements that help define the specifications processes.

The CSI Formats

CSI's MasterFormat® is the Holy Grail for organizing construction specifications with its two groups, five subgroups, 50 divisions, and thousands of section numbers and titles. This format is the standard for arranging documents within the Project Manual or Spec Book, as it is often called. The Project Manual table of contents is an extraction from MasterFormat®.

MasterFormat® sets a place to specify everything - well, almost everything. It will never be possible to predetermine every specification number and title required for every construction project. The specifier will use the overall structure of MasterFormat® to insert a custom number and title at the right location so even very specialized information can be found.

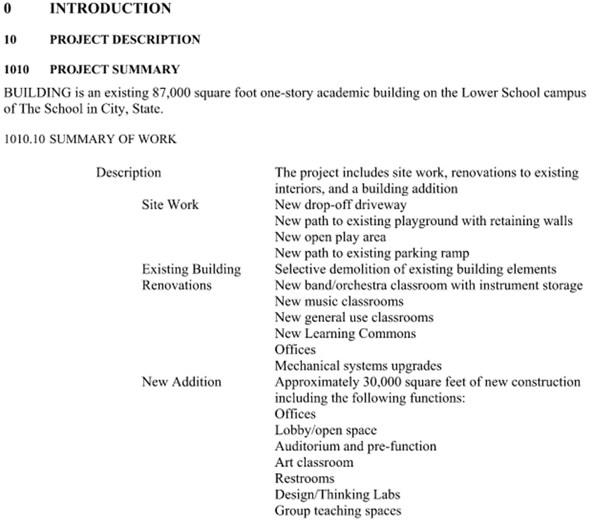

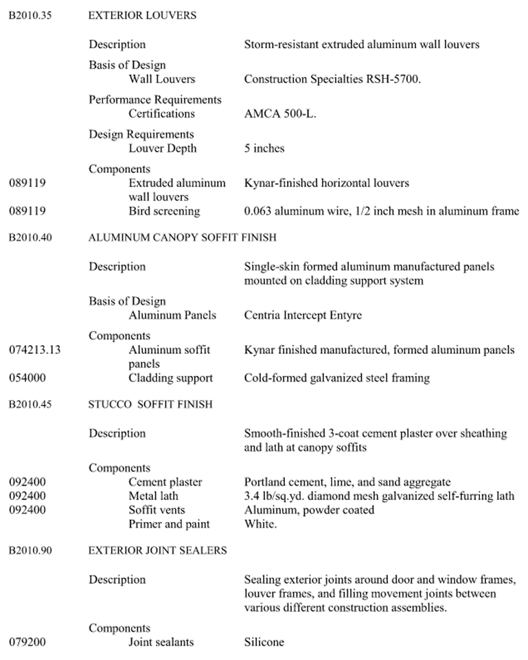

UniFormat® has an interesting history. The concept was developed by estimators as a better means of producing preliminary estimates and enabling cost analysis. This format is a classification system for building systems and assemblies, providing a framework for design and management across a building's lifecycle. It aides in early design phase decision making to define building systems and estimate project scope - including major components of the building, including site work. 1

UNIFORMAT II (ASTM E1557) is a standard classification for building elements and related site work. Elements are major components that are common to most buildings. It ensures the economic and construction feasibility to be evaluated and validated throughout the process.

The ASTM document existed before CSI's version. CSI UniFormat® extended UNIFORMAT II to include Element 0 Introduction and Z General Requirements. These two elements allow project teams to document owner project requirements and begin to identify requirements often found in Division 01 General Requirements specifications.

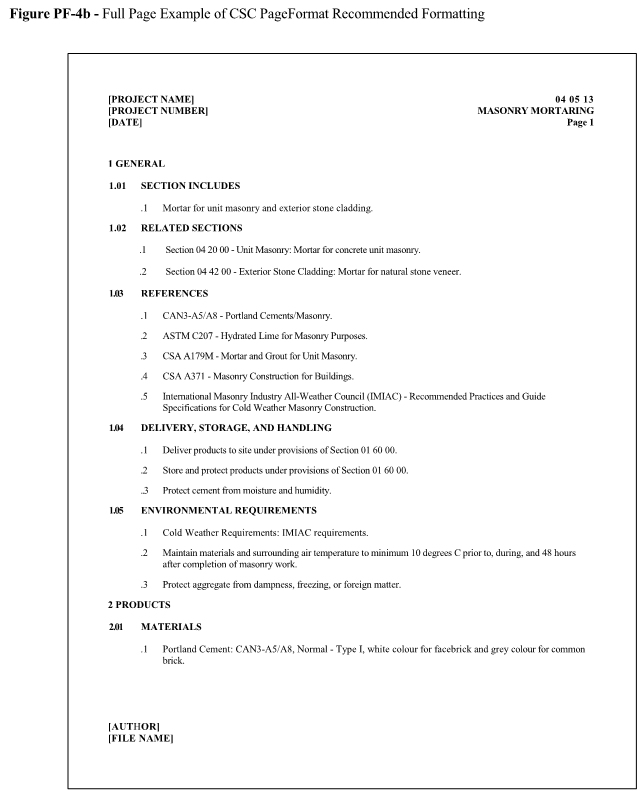

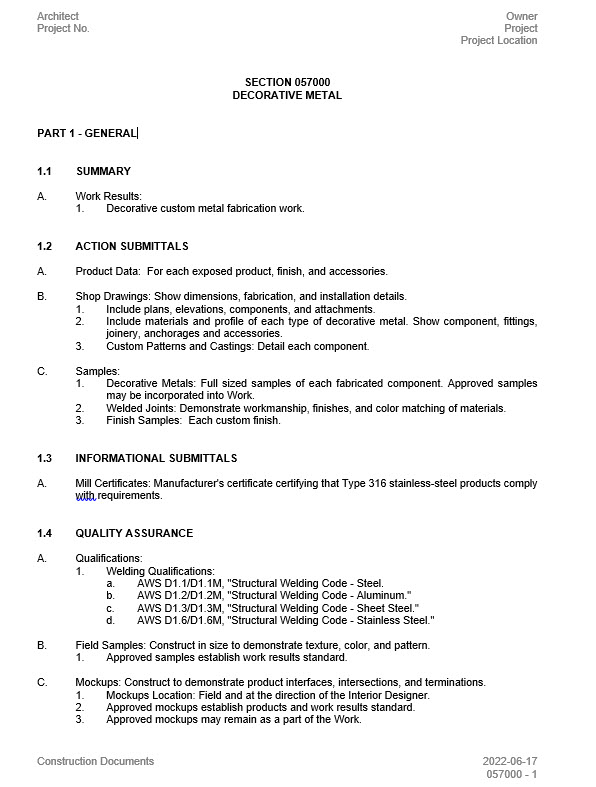

CSI's 3-Part SectionFormat™ divides each specification document into - you guessed it - three parts: General, Products, and Execution. Within each of the three parts is a standard set of article titles set in a standard order to further organize the specification data.

Finally, CSI's PageFormat™ tells specifiers how to publish specifications so the printed or electronic spec page is legible and comprehensible. The format sets details of margins, headers, footers, font size, white space, and alignment that combined have a dramatic impact on improved readability.

The AIA Processes

The AIA B101 Standard Form of Agreement Between Owner and Architect establishes the documents the architect must deliver to building owners during each phase of the design process. The defined documents include drawings, reports, and specifications.

During early phases the design may be first documented by an outline specification. AIA B101 requires an outline specification, but not until the design development phase. Schematic Design, the first design phase requires a report to identify preliminary selections for major systems and materials. This design information is easily reported in a Preliminary Design Description (PPD) that is organized by building system and assembly.

The advantage of using a PPD is that the design data and the preliminary estimate will be organized the same way - following UniFormat. Once written, the PPD can be refined and data added during Design Development to allow the project estimates to be easily compared, one complete system against another. PPDs, with the data they contain, can serve as the outline specifications required by AIA B101. It should be noted that AIA B101 does not define a specific format or organization of outline specifications.

Then construction specifications are written in accordance with MasterFormat® during the Construction Documents design phase. At this point in the project the design decisions should be complete, or nearly so. The systems and materials should be selected. Now these decisions must be documented so the contractors can construct the project to match the design intent.

A More Comprehensive Approach

Conspectus has taken this concept and has broadened the idea, removing "preliminary" from PPD and changing the title. A more efficient way of understanding and describing it is System and Performance Descriptions - SPD. This takes a descriptive approach that focuses more intently on defining systems and performance than on specific design solutions, products, and materials at the early project stages. This allows for a continuous information stream. As the design process unfolds, we continuously add and update information about system components (products and materials) to help improve the accuracy of project estimates and manage cost and time more effectively. We organize both design data and project estimates following UniFormat, a methodology originally developed by estimators. This consistency helps eliminate gaps in information flow, enables easier system comparisons, and supports optimal decision making at each critical project milestone.

Deliver on the owner's requirements. Provide early emphasis on supporting data-based design decisions and then documenting them and their rationale lays the foundation for contractually required specifications and the final set of construction documents. Having a single repository of comprehensive documentation accessible by all fosters transparency and collaboration, which means fewer RFIs, change orders, delays, claims, and disputes. It also ensures that the owner’s requirements remain the focus of design decisions throughout the process.

Penultimate Step!

Quality Assurance (QA) Review, the final step in the process, is not guided by an industry standard. It is dictated by risk avoidance to ensure the documents are well coordinated, with few (hopefully zero) inconsistencies, and buildable according to the details shown.

This last step is one that must be planned. Time must be included in the project schedule and the expense must be included in the project budget. This is one step that requires corporate commitment to enforce a policy to ensure high quality documents are delivered.

QA reviews will not happen when the design team management or the owner does not demand the review. Yet of all the design process steps, this one can have the most impact on the design team time required to complete construction. Every red mark comment on a QA document set is a potential RFI and a potential Change Order. And every RFI and Change Order is time, time that could be avoided by the QA process.

And Finally…

Implement the recommendations from the QA review. Yes, it will take time. It will be time well spent to avoid much more time later creating the documentation trail for RFIs and Change Orders.

Follow the formats and the processes to comply with the contract, to deliver quality documents, and avoid risk during construction for every project.

1 Taken from https://www.csiresources.org/standards/uniformat